Case Study

Development & Optimization of High-Performance Heat Transfer System for Armoured CarrierIntroduction

In defence applications, particularly in the case of armoured carriers, effective thermal management is crucial for ensuring reliability in extreme operational environments. Alkraft undertook the challenge of developing a high-performance heat transfer system for a new armoured carrier. The project required integrating multiple heat exchangers within a constrained space while ensuring optimal performance in some of the harshest conditions imaginable.

Project Overview

The armoured carrier was designed for deployment in desert environments, where ambient temperatures could reach up to 55°C, accompanied by high dust levels. These extreme conditions demanded a robust thermal management system to maintain the vehicle’s engine and component temperatures within operational limits. The design also had to accommodate the carrier’s limited space and airflow restrictions.

The Design Brief

Thermal Performance

Reliability & Durability

Ease of Manufacturing

Ease of Assembly

Ease of Service

Design Challenges

Significant design challenges had to be addressed during the development of the heat transfer system:

1

Restricted Air Flow

The innate design of the armoured carrier severely limited airflow, making efficient cooling a complex task.

2

Spatial Constraints

The compact nature of the engine bay provided minimal space for the installation of a complex thermal management system.

3

Extreme Environmental Conditions

The system needed to perform reliably in the high-temperature, dusty, and harsh conditions typical of desert environments.

4

Ease of Assembly, Manufacturing, and Service

Notwithstanding the system’s complexity, it had to be easy to assemble, manufacture, and maintain.

Alkraft’s Solution

Alkraft responded to these challenges by engineering a sophisticated thermal management system featuring up to ten integrated heat exchangers. This multi-layered approach was adopted to optimize heat dissipation across various components, ensuring consistent thermal performance throughout the system even in extreme conditions. Each of the heat exchangers was custom designed to meet specific cooling requirements, balancing compactness with high thermal efficiency. They were built using specially developed super-long-life alloys for best-in-class reliability and durability in harsh operational environments with high vibration, shock, and prolonged exposure to extreme temperatures and dust.

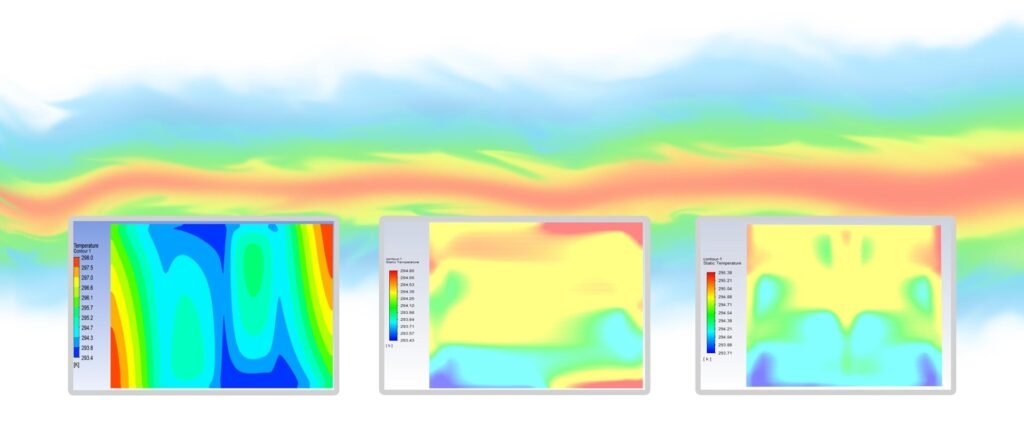

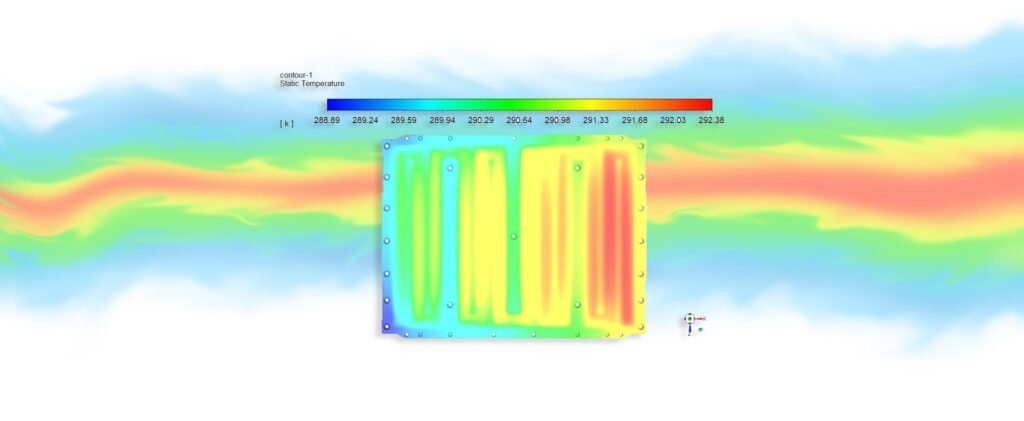

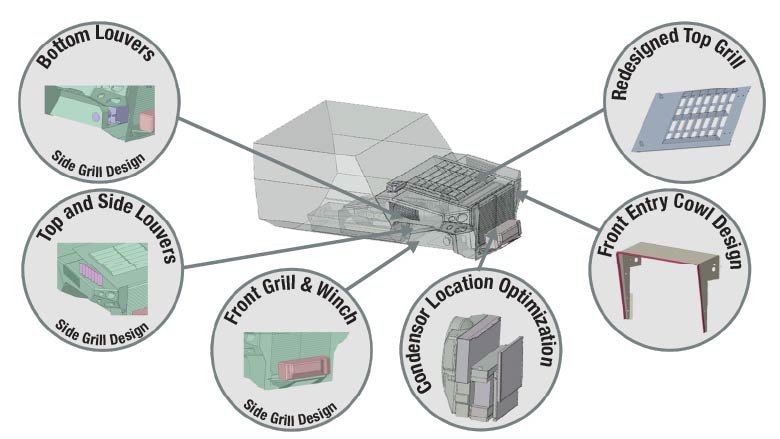

Optimization of Vehicle Hull Design

Apart from the design of the Thermal Management System, Alkraft’s design team also optimized the design of the Vehicle’s hull for adequate air flow to the heat exchangers using advanced CFD techniques. The design and placement of louvers on the vehicle’s hull played a crucial role in enhancing air flow and compensating for the vehicle’s inherent design that restricted air flow due to the armoured hull. Alkraft’s team was also responsible for matching the cooling system with the fan and the viscous fan drive in order to ensure optimal air flow and efficient thermal performance.

Project Outcome

The heat transfer system underwent rigorous testing during desert trials, where the vehicle was exposed to extreme conditions. Alkraft’s system cleared the trials on its first attempt—a clear indication of its superior performance and reliability.

The project not only met but exceeded the client’s expectations, delivering a thermal management system that ensures the armoured carrier can operate effectively in harsh environments. This project demonstrated Alkraft’s ability to overcome significant design and environmental challenges, and further enhanced its reputation as a trusted partner to the defense sector.

Conclusion

This project underscores Alkraft’s expertise in developing advanced thermal management solutions tailored to specific client needs in challenging environments. The successful development and optimization of the heat transfer system for this armoured carrier exemplifies Alkraft’s commitment to innovation, reliability, and engineering excellence. Alkraft continues to be a preferred provider of cutting-edge thermal management solutions that ensure the operational effectiveness of military vehicles under the most extreme conditions.

View Other Case Studies