Case Study

Collaborative Innovation in Development of BS6 Thermal Management SystemThe transition to BS6 emission norms in India presented significant challenges to the automotive industry. As emissions regulations tightened, the need for advanced cooling systems became critical. The case study presented here explores how Alkraft, in partnership with a Commercial Vehicle OEM customer, developed a groundbreaking thermal management system for a truck designed from the ground up, overcoming significant challenges through design collaboration and novel engineering approaches.

Redefining Thermal Management for BS6

The development of a thermal management system for BS6-compliant trucks was a complex task. Alkraft faced several key challenges:

1

Increased Thermal Performance in Constrained Space

The new BS6 trucks required significantly higher levels of thermal performance, but the available space for the cooling system was more constrained compared to the earlier BS4 models.

2

Cost Constraints

Developing an advanced thermal solution within a cost target feasible for the Indian market was another major hurdle. The balance between innovation and affordability was critical.

3

Extended Product Life

The target life expectancy for the thermal management system needed to be doubled—from 1.5 years to 3 years—while maintaining reliability and performance.

The Approach:

Early Involvement and Radical Design Changes

Alkraft’s approach to solving these challenges began with early involvement in the customer’s product development process. By engaging with the customer at the conceptual stage, Alkraft could provide valuable input on key aspects such as thermal challenges, airflow management, heat transfer system packaging, and mounting solutions.

One of the most significant aspects of this collaboration was the customer’s willingness to adopt a radically different design approach and was crucial to the project’s eventual success. The collaboration led to several innovative solutions:

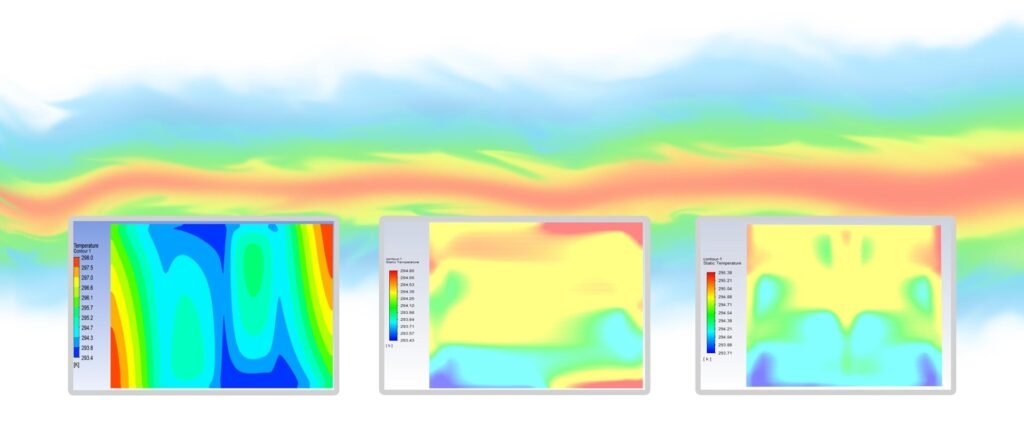

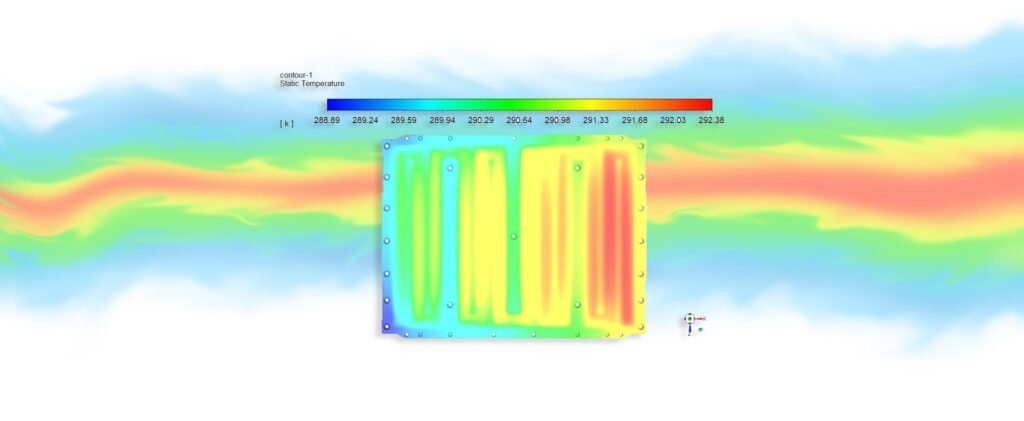

Smart Core Design

Alkraft introduced its 4th generation of folded tubes, along with a new fin geometry which played a central role in enhancing heat transfer efficiency while optimizing the system’s weight and durability.

Proportional Design and Core Geometry

The new system featured a wider and more proportional design with less overhang and a core geometry with greater tube density. This not only improved thermal performance but also reduced the system’s mechanical and thermal shock susceptibility.

Material Optimization

A thorough re-evaluation of material selection led to the use of optimized materials that enhanced the system’s overall performance and durability.

The Result: The Best-in-Class BS6 Thermal Management System

Completely redesigned Radiator Frame Mounting for better durability and vibration resistance

Sliding Joint design to minimize the imapact of thermal fatigue and thermal shock

The collaborative efforts between Alkraft and the CV OEM resulted in a BS6 thermal management system that surpassed all expectations. The end-product met the stringent BS6 thermal performance, reliability, and durability parameters. Some of its notable features were:

1

Enhanced Durability

The radiator frame mounting was completely redesigned for better durability and vibration resistance. The tank was also redesigned with external ribs for extra stiffness to withstand pressure pulsation.

2

Improved Vibration Dampening

The CAC (Charge Air Cooler) mounting brackets were redesigned on both the top and bottom sides with rubber bushings, significantly improving vibration dampening.

3

Optimized Core Design

The new core, featuring Alkraft’s proprietary 4th generation folded tubes and high-performance fin geometry, delivered exceptional thermal efficiency.

4

Better Weight Distribution

The repositioned stay connection at the bottom side reduced overhang, leading to a more proportional design and improved weight distribution.

5

Sliding Joints to prevent failures

The BS6 system featured sliding joints that provided allowance for expansions and contractions due to temperature variations. This helped prevent failures resulting from thermal fatigue.

6

Zero Failures and Cost Efficiency

Remarkably, the new system had zero failures in the field, demonstrating its robustness and reliability. Moreover, the value engineering efforts led to a significant cost reduction, making the product more competitive in the market.

Conclusion: Innovation Through Collaboration

The successful development of the BS6 thermal management system by Alkraft underscores the importance of early collaboration, innovative thinking, and a willingness to challenge traditional approaches. By working closely with its customer and embracing new design philosophies, Alkraft was able to deliver a product that not only met the stringent requirements of BS6 norms but also set new benchmarks in performance, durability, and cost efficiency. As the automotive industry continues to evolve at a much faster pace, such collaborations will be crucial in driving innovation and delivering solutions that meet the ever-changing demands of the market.

View Other Case Studies